Milling is today a modern and continuous process with traditional skills

Most European wheat is consumed in the form of flour. Today, the range of flours and breads available is wider than ever before. The skill of the European flour miller is paramount in ensuring that different types of wheat are gristed and milled to make flour with specific uses in mind.

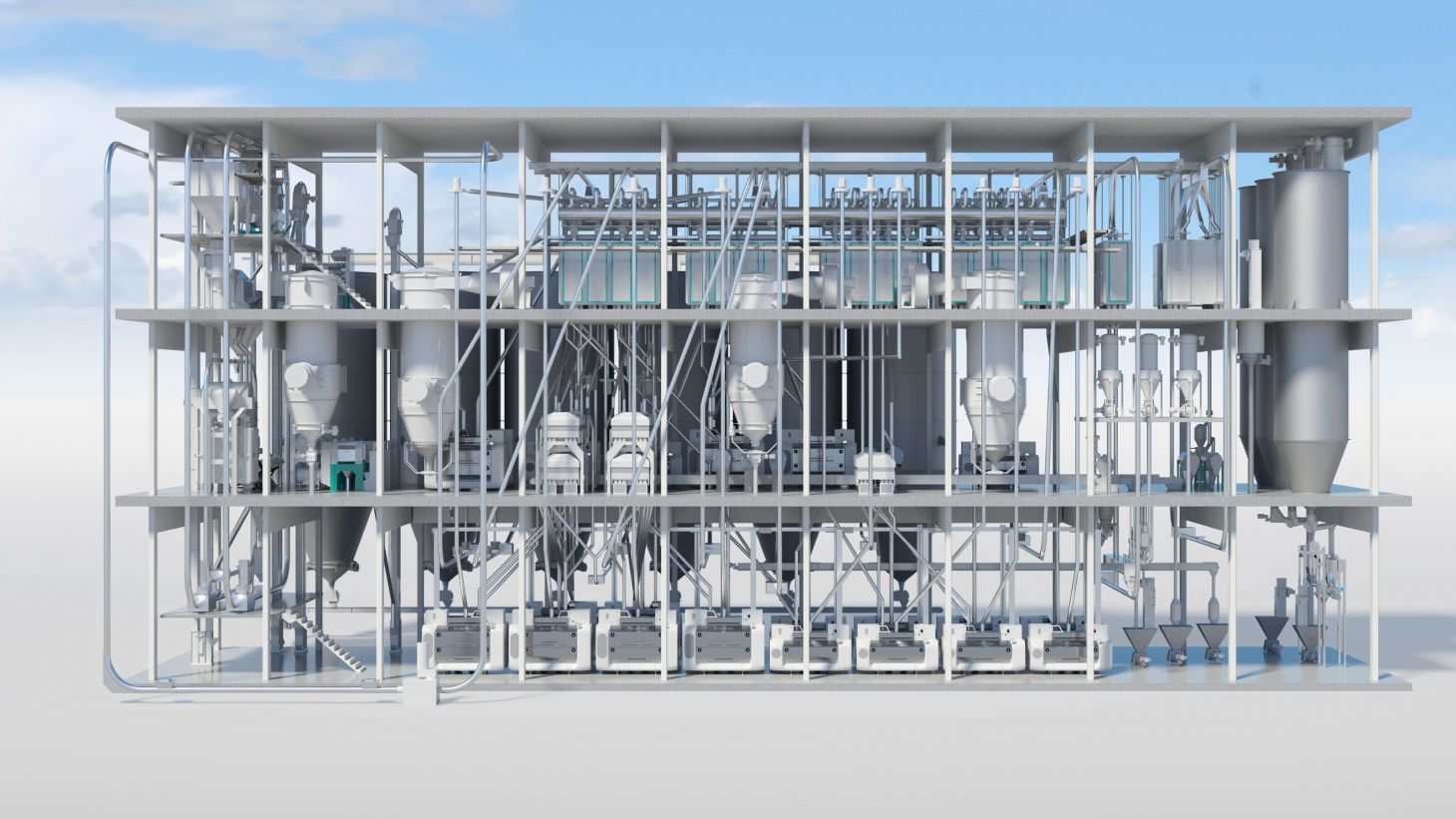

The milling process

The milling process has evolved from the days of grinding the wheat between two large stone wheels (although this process does still occur in a few mills), to the modern rollermill.

The modern rollermill consists of two cast steel rollers set slightly apart from each other. The top roller runs at a slightly faster rate to the lower roller; when wheat passes through it creates a shearing action, opening up the wheat grain.

The various fragments of wheat grain are separated by being passed through a complex arrangement of sieves. White endosperm particles known as semolina will be channelled into a series of smooth reduction rolls for final milling into white flour.

Modern flour mills operate without interruption

Milling is a continuous process. Flour mills are operating 24 hours a day, seven days per week with infrequent maintenance shutdowns. Thus, millers must secure regular access to agricultural raw materials in the required quantity and quality.

The high standards of cereal flours in Europe

Food safety and quality have reached a very high standard in the EU. Flours vary in their composition and, broadly speaking, are defined by the quality of grain used in the grist prior to milling and by their rate of extraction. A typical European mill will produce hundreds of different types of flour using a wide range of home-grown and some imported high-quality wheat. Safety rules are known as the strictest in the world.

Basic flour categories according to extraction rate

All wheat flours vary are classified according to the percentage of wheat grain present. This is know as the extraction rate. Wholemeal flour contains the whole grain and is therefore a 100% extraction-rate flour. Brown flour contains about 85% of the grain and white flour between 75-80% extraction.

- White - usually 75% of the wheat grain. Most of the bran and wheatgerm have been removed during milling.

- Wholemeal - 100% extraction, made from the whole wheat grain with nothing added or taken away.

- Brown - usually contains about 85% of the original grain, some bran and germ have been removed.

More unusual flours such as buckwheat, sorghum and spelt flours are also increasingly common and many European mills can now blend bespoke flours for specific customers.